Fully Factory Refurbished Machinery

At Rühle we understand the importance of having well-functioning and reliable equipment, and that's why we have a dedicated team of experts who specialize in the refurbishing process.

The refurbishing process begins with a comprehensive inspection to assess the condition of the equipment. Issues are identified, which can range from simple repairs to more complex overhauls that require the replacement of parts. Once the repairs are complete, the equipment undergoes rigorous testing to ensure it functions as intended. We believe that refurbishing machinery is not only cost-effective but also environmentally responsible and by extending the life of equipment, we are minimizing waste and promoting sustainability. Our skilled engineers and technicians are committed to excellence and take pride in their work, ensuring that every piece of machinery that leaves our facility is of the highest quality and restored to its original condition.

The confidence we have in the refurbishment process of our used machines, allows us to offer you a full factory warranty... just like all our new machines.

Rühle AR10 Dicer

Specifications

Machine length: 1.070 - 1.900 mm

Connected load: 400 V, 3.8 kW, 16 A

Machine width: 690 - 890 mm

Performance: max. 1.700 kg / h

Machine height: 1.040 mm

Machine weight: 245 kg

Shaft length: 350 mm

Shaft width: 100 mm

Shaft passage height: 100 mm

Section length: 0,5 - 60 mm

Sections: 200 per minute

Cutting temperature: -5 °C - +80 °C

Standard grid sizes: 3, 5, 6, 8, 10, 12, 15, 16, 20, 24, 30, 50

Rühle SR2 Bi-Turbo Dicer

Specifications

Machine length: 1.555 mm

Connected load: 400 V, 5.3 kW, 16 A

Machine width: 1.026 - 1.575 mm

Performance: max 3.000 kg / h

Machine height: 1.470 mm

Machine weight: 695 kg

Shaft length: 500 mm

Shaft width: 120 mm

Shaft passage height: 120 mm

Section length: 1 - 30 mm

Sections: 0 - 300 per minute

Cutting temperature: -5 °C - +80 °C

Standard grid sizes: 5, 10, 20, 60 / 6, 12, 24, 60 / 7, 15, 30, 60

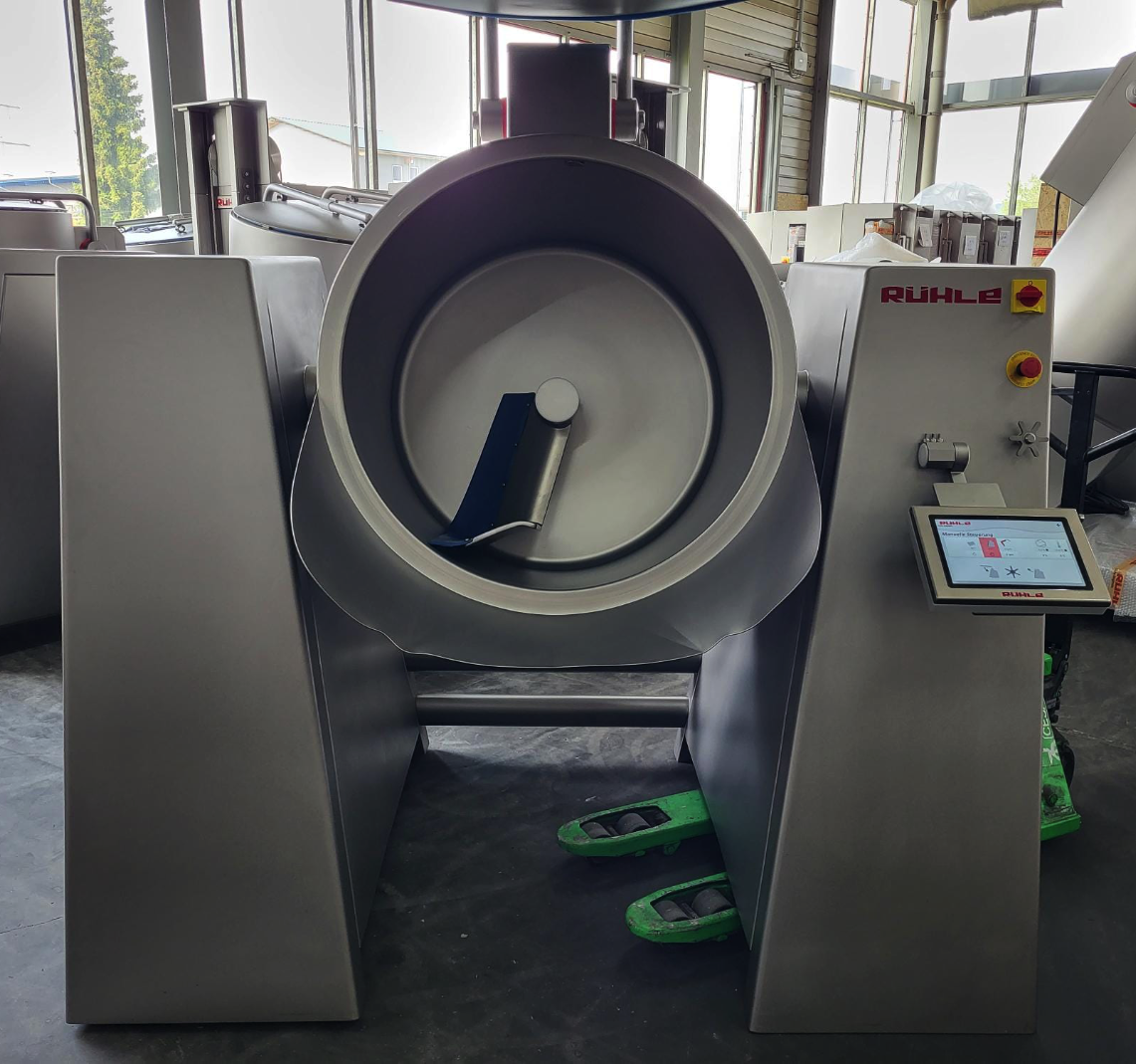

Rühle MPR600Lt Vacuum Tumbler

Specifications

Machine length: 2.200 mm

Connected load: 400 V, 6.8 kW, 16 A

Machine width: 1.350 - 2.995 mm

Cooling: R 452 a

Machine height: 2.000 - 2.930 mm

Machine weight: 1.760 kg

Filling capacity: 410 l

Container size: 600 l

Continuous arm drive: 0 - 30 Rpm

Vacuum system: 0 - 90 %