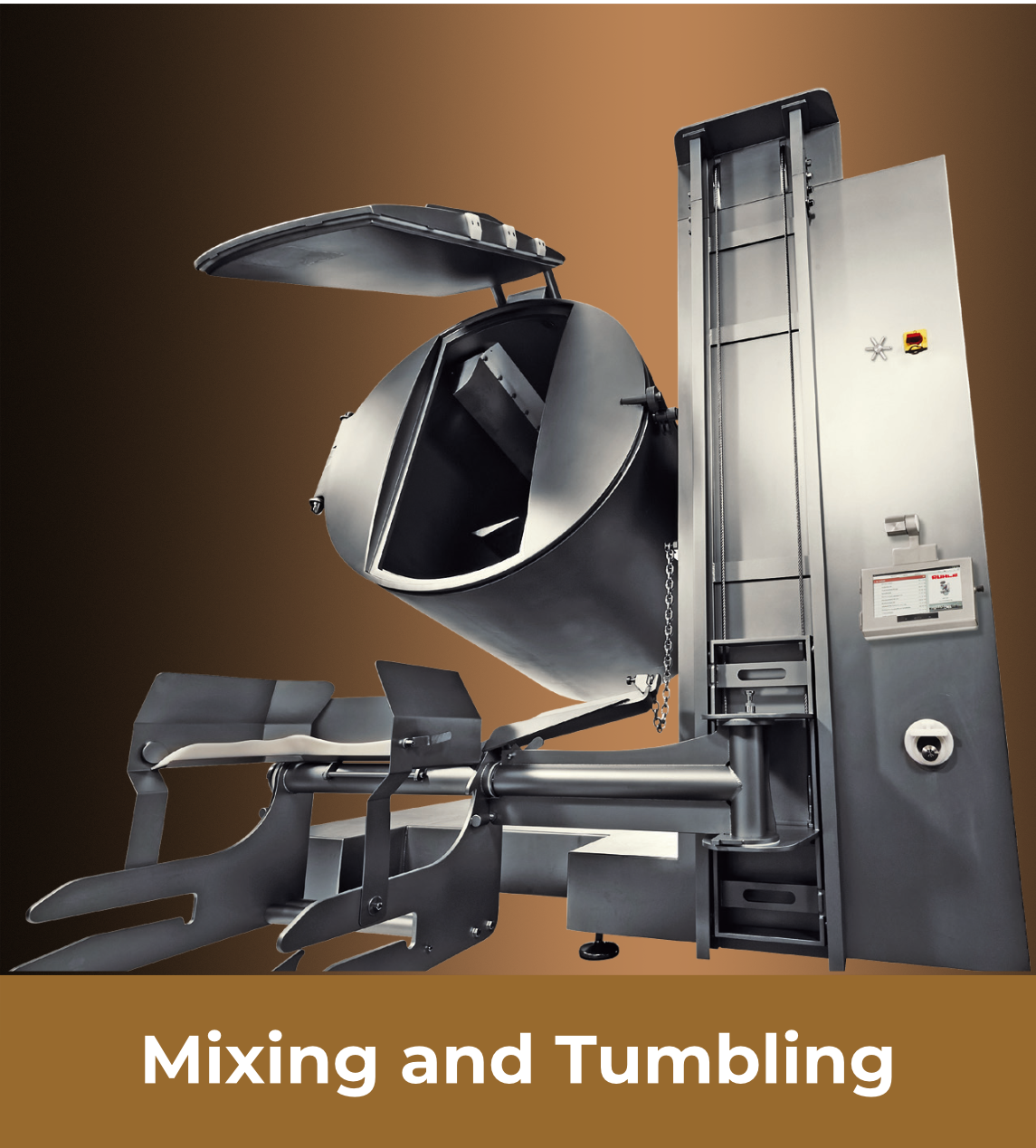

New Rühle Mixing and Tumbling Machines - Powerful mixing and intensive kneading with real HighTech

New Rühle Original MPR 220 Turbo - Mixing, tumbling and marinating

Contact us for price

or call

+44 774 263 4005

Description

Mixing and kneading - The container can be tilted to different angles. The large - diameter container enables good rolling of the mixing product. The rotational speed of the mixing arm ranges from 0 to 50 rpm. An arm with a large working surface, but no edges or angles, does the rest.

Precise temperature control - The powerful cooling unit inserts the coolant directly into the perfectly insulated container. This enables very fast temperature regulation and very precise adaptation to all temperature requirements. Optionally, the cooling unit can be run as a heat pump and supply heat up to 80 °C.

Feeding system 150 - liter trolley - A reinforced machine frame and an integrated feeding fork enable easy feeding using a 150 - liter trolley. Nothing can be spilled when the container is being swiveled and the lid is opened. The simultaneously moving tumbling arm conveys the product entirely out.

Flexible programming - Twelve parameters are easily accessible at any stages. Recipes can be created intuitively, and everyday tasks are easily facilitated by a smaller control interface. All made possible by perfect software and reliable hardware.

Accurate machine positioning - Automated drives enable the machine to change its working position randomly. The result is process intensity that is perfectly adapted to the product mix. These automatic aids make filling and draining very easy.

Hard working and perfect scraping - The outer contour of the mixing arm is designed for gentle handling and processing of delicate products. A rotating scraper keeps all container surfaces perfectly clean. Everything remains within the mixture and nothing is left unprocessed.

Specifications

Machine length: 1.200 mm

Connected load: 400 V, 4.2 kW, 16 A

Machine width: 1.026 - 1.418 mm

Cooling: R 452 a

Machine height: 1.511 - 2.020 mm

Machine weight: 720 kg

Filling capacity: 160 l

Container size: 220 l

Undercarriage: 4 castors

Continuous arm drive: 0 - 50 rpm|

Vacuum system: 0 - 90 %